PRODUCTS

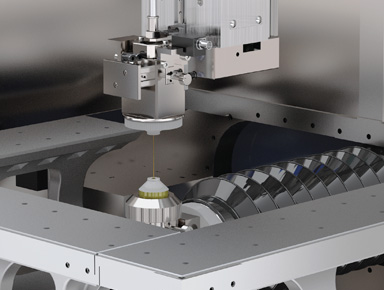

Introducing the CNC Wire Cut E.D.M Series produced by SPM.

What is the Wire-cut EDM

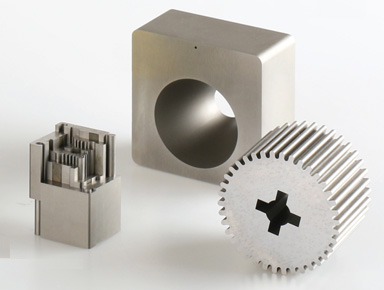

The Wire-cut Electrical Discharge Machine is a machine tool that uses a wire, typically made of brass or copper with a diameter of around 0.25㎜, positioned close to the metal workpiece, discharging a strong current to cut the metal. It is widely used for manufacturing complex shapes or fine components and is increasingly applicable to various newly discovered materials, making it a high-value machine tool. Unlike other cutting machines, the wire-cut EDM has the distinctive feature of being able to cut workpieces that are electrically conductive, such as carbide alloys, quenched heat-treated steel, and stainless steel, which are typically difficult to process. It can also perform forming and high-precision machining. The small force used in the process minimizes strain on the machine, and for complex machining tasks, it can be easily handled by linking with an NC program. Additionally, it is advantageous in reducing or expanding the gap between dies and punches or rotating them in various ways. Since discharge occurs in a narrow machining area, heat deformation is minimal, which helps minimize the physical distortion of materials, especially in components where precise shapes and dimensions are critical. It is also effective for machining heat-sensitive materials, and automation through NC control allows for unmanned processing with program settings. This results in cost savings and improved productivity.

The development of wire-cut EDM began in the 1960s. The Electronic Discharge Machine technology originated in the 1940s, when spark discharge was experimentally used to cut metal. However, research into indirect cutting methods using wire began in earnest with the development of discharge machining technology. Specifically, the Soviet couple Lazarev and Benitov invented the first manual feed wire-cut EDM, laying the technical foundation for the field. By the 1960s, wire-cut EDM were developed and commercialized in Switzerland and Japan. In South Korea, it was first introduced in the late 1970s to early 1980s, coinciding with the global commercialization of the technology. South Korea imported the equipment from Japan, its neighboring country, and from the 1980s to the 1990s, the use of wire-cut EDM expanded, especially in industries requiring precision such as electronics, automotive, and semiconductors.

SPM Co., Ltd. played a pivotal role in achieving technological independence in South Korea's machine tool industry by launching its independently developed CNC Wire Cut EDM in June 1995. Today, wire-cut EDM is actively used in industries requiring precise and complex machining, such as aerospace, automotive parts, and electronic components.

Applicable industries

-

Press industry

Wire-cut EDM, capable of precise machining of complex shapes or fine details, are particularly advantageous in creating angular or curved components, as well as performing hole machining that cannot be done with traditional press molds. The wire-cut EDM helps overcome the limitations of press molds, enabling the production of parts with desired shapes, thus expanding its demand.

-

Mold industry

Wire-cut EDM is predominantly used to machine detailed parts and complex shapes in mold manufacturing, due to their excellent precision. They are employed in areas where precise shape machining or finishing is required, contributing to higher mold quality. Recently, as demand for small-batch, high-precision production has increased in industries like plastics, electronics, and automotive, the reliance on wire-cut EDM technology has grown significantly.

-

Parts industry

Small quantity many species production lowers product unit cost being generalized, without manufacturing troy than production by expensive troy manufacture way product tendency that process direction discharge become much and is generalized in parts processing of Airline industry and so on specially.

ENG

ENG KOR

KOR